In a world where aesthetics are the most important element of a space, people often find themselves drawn to hardwood products despite their price tags.

The process of manufacturing hardwood is labor-intensive, especially if it is done the right way.

Let’s dive into hardwood products and why they are worth every dollar.

Factors that Affect the Price of Hardwood

Hardwood products are more expensive than alternatives for several reasons.

Wood Species

Hardwood species have different characteristics, availability, demand, and quality. For example, if a hardwood species is seen in a celebrity house and is aesthetically pleasing, it can cause a cultural trend, which impacts demand, availability, and price.

Grade and Quality

All industries have regulations and standards that are in place to set the bar for specifications and procedures for materials, products, methods, and services that we rely on every day, which are consistent and reliable. The National Hardwood Lumber Association created hardwood regulations to ensure hardwood lumber is uniform during production.

Each board of hardwood manufactured at Gutchess Lumber is inspected a minimum of four times by trained graders following NHLA grading guidelines, ensuring that we are producing the highest-quality hardwood possible.

Market Demand and Supply

Fluctuations in hardwood demand can influence prices. Shortages or surpluses of hardwood species can also affect market prices and availability. When the need for wood materials and products exceeds the supply, the cost will rise. A delicate balance between supply and demand directly influences hardwood prices.

Demand is heavily influenced by construction activity.

Transportation and Import Costs

Transporting hardwoods to other markets involves various expenses, such as shipping, handling, and import duties. Some hardwood species are only found in specific regions around the world, which will also increase the price of the final product.

Gutchess Lumber has exported its real American hardwood products worldwide for 100 years, and we know every aspect of shipping.

Labor Costs

Skilled laborers are required to manage forests, harvest timber, transport logs, and manufacture, dry, and ship hardwood products. Hardwood is a natural material, so it is more difficult to process. The labor and skills needed to process hardwood and the need for heavy machinery contribute to its high costs.

At Gutchess, our products come from well-managed forests and timberlands in the northeast, several of which we have owned and managed ourselves for generations. We employ a team of over 40 foresters who have a combined experience of 250 years. Costs come with experience, and the team needed to ensure our hardwood is responsible and sustainable. A cost we believe is one hundred percent worth it. We hope you do, too.

Our process starts with the boards being sawn in our modern band mills, dried in our state-of-the-art kilns, and inspected by highly skilled and well-trained lumber inspectors at least four times, green and dry, to ensure accurate grade and tally, consistent quality, and maximum yield. This process requires skilled workers with extensive knowledge of hardwood and sawmills.

Seasonality and Weather Conditions

Weather and environmental conditions can impact tree growth and harvesting, which directly influences the availability and price of hardwood. Unpredictable natural events, such as wildfires, droughts, and pest infestations, can damage forests and result in a scarce supply that increases prices.

FUN FACT: The emerald ash borer (EAB) is slowly causing the Ash hardwood species to die out. This invasive beetle has killed nearly 100% of ash trees infested with EAB. Specialists predict that the EAB will cause the Ash hardwood species to become extinct. The Ash species is commonly used for baseball bats, flooring, furniture, lumber, and pallet manufacture.

A region’s climate directly relates to the health and productivity of its hardwood production. Regions with stable conditions and temperatures, a healthy amount of precipitation, and lots of sunlight are more suitable for tree growth, which is why the Northeastern region of the United States is the ideal region for souring hardwood that goes into making products. When predictable climates occur, the manufacturing process of hardwood can become more efficient.

Since 1904, Gutchess Lumber Co., Inc. has produced the finest quality northern hardwood lumber through our vertically integrated manufacturing facilities across New York and Pennsylvania. Each of our hardwood species is native to the northeast United States. This means we can control the process from harvest to order fulfillment while keeping our operations sustainable by only harvesting within 150 miles of each of our 7 locations.

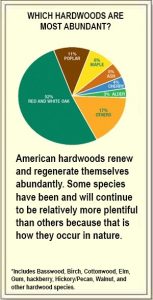

The Most Common Hardwood

The most common hardwood varies by region, but globally Oak is most common hardwood. The American Hardwood Information Center found that 52% of American Hardwoods are oak, growing mostly in New England to Mississippi. American hardwoods typically grow in the Eastern part of the country due to soil types and nutrients, moisture, earth, and sunlight. American hardwood forests are responsible for providing hardwood for products like cabinets, flooring, millwork, and furniture. Red and White Oak are commonly used for these products and are the most abundant in the United States.

At Gutchess Lumber, we specialize in sourcing Northern Red Oak from forests within a 100-mile radius of our New York and Pennsylvania manufacturing facilities. Unlike southern Red Oak, which commonly has discoloration and other issues, our true Northern Red Oak offers a consistent color profile and grain that rivals White Oak.

How to Find Your Perfect Hardwood

Using hardwood offers beauty, durability, and value.

Research: Research different types of hardwoods and their characteristics. Understand the pros and cons of each type, what they are used for typically, and their sustainability and durability.

Visit Suppliers: Visit local sawmills, woodworking stores, or specialty suppliers to see and feel the hardwood in person. Each hardwood species has its own unique feel and look, so you will get a sense of its appearance and quality.

Consult Experts: Talk to woodworkers, carpenters, architects, or hardwood sales representatives in your area who can offer advice based on their experience and knowledge. They will also know what wood is most affordable in your region and which will work best for the product you want to create or buy.

Testing the Product: If it is available, try to purchase a small sample of the hardwood you are looking at and test for workability, finishing, and appearance for your specific needs.

Evaluate Options: Compare the hardwoods based on your research and tests, budget, and consider all the factors like durability, aesthetics, and sustainability before creating your product.

The type of hardwood will depend on what product you are creating. William Walker, a woodworker, made recommendations on what woods are best based on products and projects.

The Value of Hardwood and Why it’s Worth It

Hardwood is a valuable material that is durable, timeless, adaptable, and sustainable, making it a top choice for products and projects of all kinds. It continues to prove to be a great investment based on its lifespan, maintenance over time, and the ability to refinish and repair it. It comes in a variety of colors and finishes, bringing any project or product to life. If you choose hardwood, you invest in a material that offers value and sustainability, making it worth the cost.

For high-quality hardwood, Gutchess is committed to providing the best of the best hardwood species. Use our interactive map to locate your region’s dedicated sales representative today.