Hardwood Species Highlight: Hard Maple vs Soft Maple Wood

Sugar Maple trees grow abundantly and are popular for what is on the inside- Maple Syrup and Hard Maple lumber! Hard Maple lumber has common uses in furniture, hardwood flooring, cabinets, sports equipment, kitchen accessories and more, allowing for this light-colored lumber to be featured in each aspect of your home. Hailing from the Sugar Maple tree, this incredible wood is a staple species that Gutchess Lumber manufactures.

Sugar Maple growth

The Sugar Maple (Acer Saccharum) tree grows throughout the Eastern United States, Canada, and the Great Lake states, specifically: through central Ontario, the southern third of Quebec, all of New Brunswick and Nova Scotia, throughout New England, New York, Pennsylvania, the mid-Atlantic states, extending southwest to New Jersey and to the Appalachian Mountains, downward to the western edge of North Carolina and the Southern border of Tennessee. The western limit for Hard Maple lumber growth extends through Missouri and into small areas of Kansas, Iowa, and Minnesota. There are a few outliers of Sugar Maple hardwood growth in Kansas, Georgia and the Carolinas.

Its ideal growing climate is cool and moist which is why it is restricted to these regions. That said, it can grow on sand, loamy sand, loams, and silt but it does best on well-drained loams. It does not grow well on dry, shallow soil and is very rarely found it swampland.

Early growth of Sugar Maple trees is slow as they often are regenerating under heavy canopies and shade, though of deciduous trees, they are among the most shade tolerant. The minimum seed-bearing age for Sugar Maples is roughly 30-years. Sugar Maples are a long-living tree, typically reaching 200-years to 300-years in age. The areas in which they reside, where they are hard freezes in the winter for proper dormancy, encourage this slow and long life.

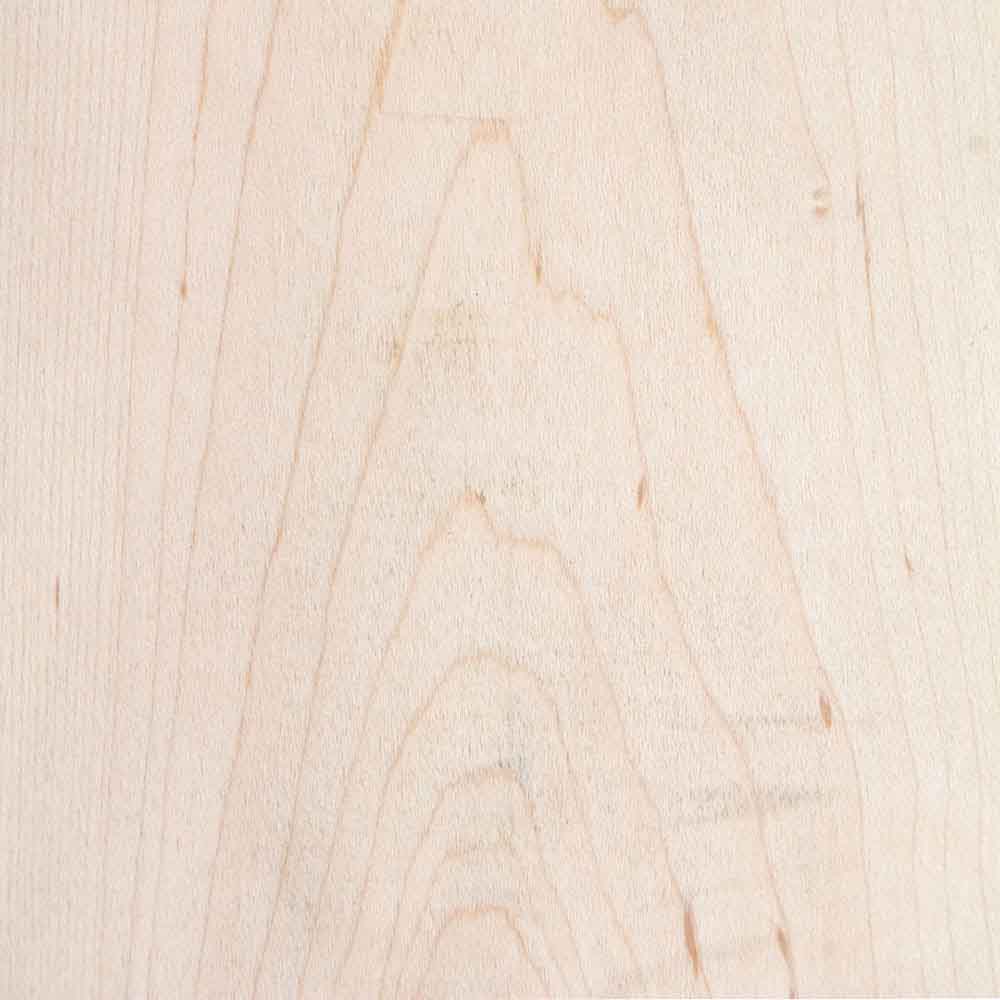

Difference between Hard Maple and Red Maple grain

Differences between Hard Maple and Soft Maple

Hardwood species are classified by the seeds the tree produces. Each hardwood tree species has a coating that takes the shape of a fruit or a shell that becomes a flowering plant. These flowering seeds are known as angiosperm, which translates in Greek to “vessel seed.” Additionally, hardwood trees lose and regrow their leaves annually, making them deciduous.

They differ from softwood trees, as trees classified as softwoods seeds do not have any coating and are instead, dropped to the ground to deal with the elements. Examples of softwood tree seeds are needles and cones that are dubbed gymnosperm, meaning “naked seed.” Except for the Larch tree species, all softwood trees retain their needles year-round, making them evergreen trees.

That said, “Hard Maple” and “Soft Maple” do hold distinct meanings when referencing the tree species. The term “soft maple” is used to reference several different types of maple trees, including Red Maple, while “Hard Maple” specifically references the lumber that comes from the Sugar Maple tree and, on occasion, the Black Maple tree. Both Soft Maple and Hard Maple are harvested from dicot trees, making them both hardwoods. Soft Maple wood comes in many varieties and is 25% softer than Hard Maple wood.

Difference between Oak and Maple wood

Appearance and hardness are the biggest differences between Oak and Maple wood. Maple wood appears less “grainy”, has smaller pores compared to Oak wood, and is a white or cream colored hardwood. Oak wood has a distinct grain pattern and colors that range from a yellow-white to reddish brown, depending on the species. In terms of hardness, Hard Maple hardwood has a Janka hardness score of 1450, while Soft Maple has a hardness score of 950. Red Oak scores 1290 and White Oak scores 1360 on the Janka hardness scale. You must know which species you are comparing to determine the specific difference between Oak and Maple wood.

Hard Maple density

The Janka Hardness Scale is used to determine the relative hardness for domestic wood species, like Hard Maple hardwood. The test measures the amount of force that is required to embed a 11.28mm steel ball halfway into a piece of wood. While the Janka Hardness Scale is traditionally used to determine whether a wood species is suitable for flooring, it is a good measure of determining a wood species resistance to wear and its overall durability. Wood species with a higher number rating are harder than wood species with a lower rating. The data from the Janka Hardness Scale is expressed in pounds-force, or lbf.

On the Janka Hardness Scale, the Hard Maple hardwood species rating is the highest of all the Maple hardwood species. Hard Maple has a Janka Hardness Scale value of 1,450, while its soft maple relative, the Red Maple, has a rating of 950 lbf. When compared with other hardwood species, Hard Maple wood falls in the middle of the Janka Hardness Scale. It is less durable that Red Oak wood and White Oak wood but marginally more durable than Cherry wood.

Different types of Maple wood

- Sugar Maple (Acer saccharum): this maple hardwood species is one of two hard maple wood types. It is also the first choice for those seeking to make maple syrup. It grows to a height of 50 to 80 feet, is abundant throughout the Northeastern and Southern United States and Northeastern Canada, and is one of the species of maple that Gutchess Lumber manufactures.

- Black Maple (Acer nigrum): this maple hardwood is the second of two hard maple wood types. It is incredibly closely related to the standard Sugar Maple tree and as such, is commonly known as the Black Sugar Maple. This Maple hardwood species grows between 80-115 feet tall in the Northeastern and Southern United States and Northeastern Canada.

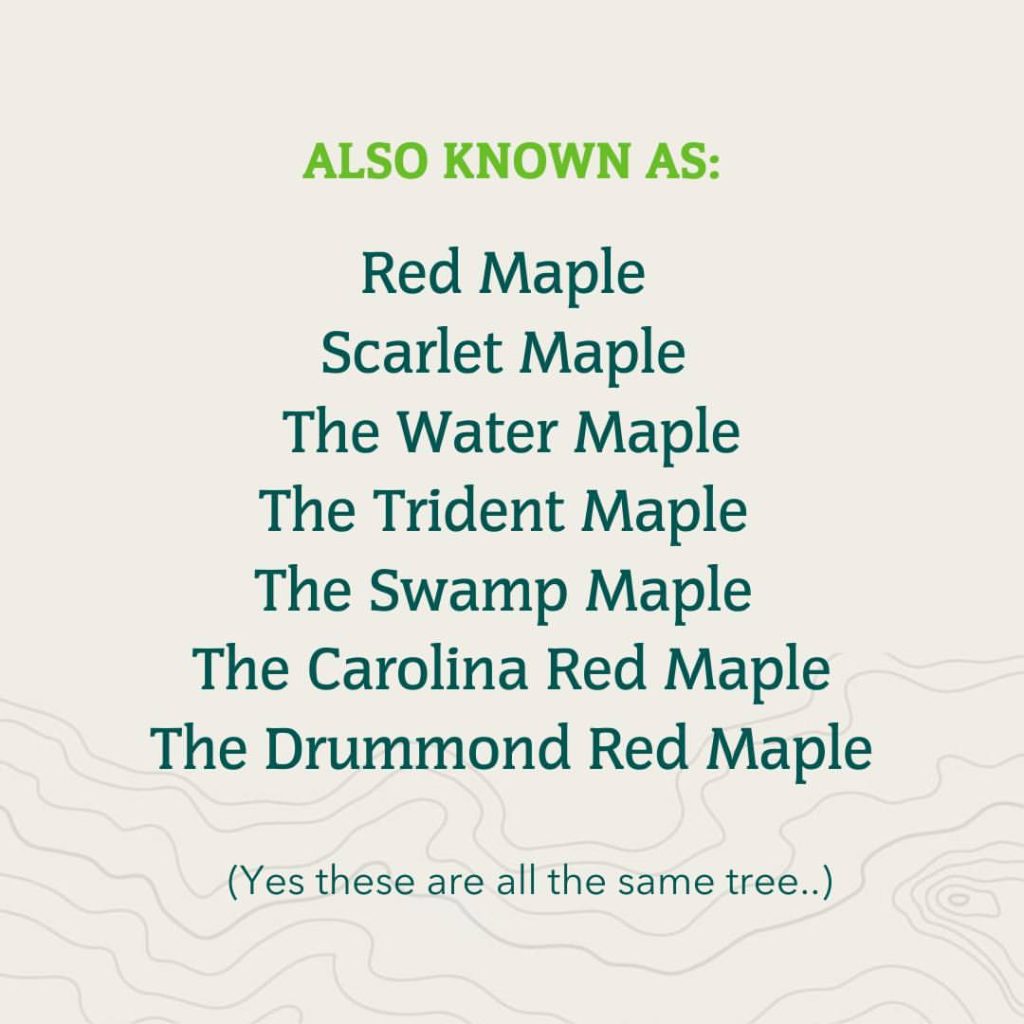

- Red Maple (Acer rubrum): dubbed for its red leaves in the autumn, the Red Maple tree also is known as the Scarlet Maple, the Soft Maple, the Drummond Red Maple, the Carolina Red Maple, the Swamp Maple, the Trident Red Maple and the Water maple. It is a soft maple hardwood tree that grows from 30 to 100 feet in its native area of the Eastern United States and Canada.

- Silver Maple (Acer saccharinum): like the Red Maple, the Silver Maple gets its name from the leaf color, with the underside of its leaves reflecting a silver flash in the wind. It goes by various names regionally, including the Soft Maple, the Creek Maple, the River Maple, the White Maple and the Water Maple. Growing from 50 ft to 100 ft in its native region of the Eastern United States and Canada, this Maple tree type is over of the most abundant.

Birdseye Maple vs Spalted Maple

Maple wood species are commonly referred to by other names. While these names, like Birdseye Maple and Spalted Maple are popular, they are indicative of character traits of the lumber and are not, in fact, a Maple species.

Birdseye Maple, sometimes written as bird’s eye maple, was given its name due to the tiny knots in the grain that resemble a small birds eye. Birdseye Maple is in actuality Hard Maple lumber. The figuring of the lumber is caused by an unfavorable growing condition for the tree and as the tree makes repeated attempts to start numerous new buds to increase the amount of sunlight it is receiving, with the poor growing conditions the new shoots are abandoned and a number of tiny knots remain. The “defect” created by these growing conditions make for a incredible Birdseye Maple boards.

Like Birdseye Maple, Spalted Maple refers to a defect created by growing conditions and not a wood species itself. Spalting is a fungal discoloration of wood, not exclusive to the Hard Maple wood species. Spalted Maple can be found in wood that has begun its initial stages of decay and then subsequently dired to prevent further decay. Spalted Maple, otherwise known as Black Line Maple, is referred to as the latter because of the dark, contrasting lines and streaks created by fungus in decaying wood.

Birdseye Maple and Spalted Maple are similar in the way that they are both common defects produced in the Maple hardwood species. They have become so common that they fall in line with the actual tree species that fall in the wood type. While they share similarities in being defects, the Birdseye defect is most notable in Hard Maple wood, while Spalting can be commonly found in Sycamore Trees, Beech trees, Birch trees, Hickory trees and others.