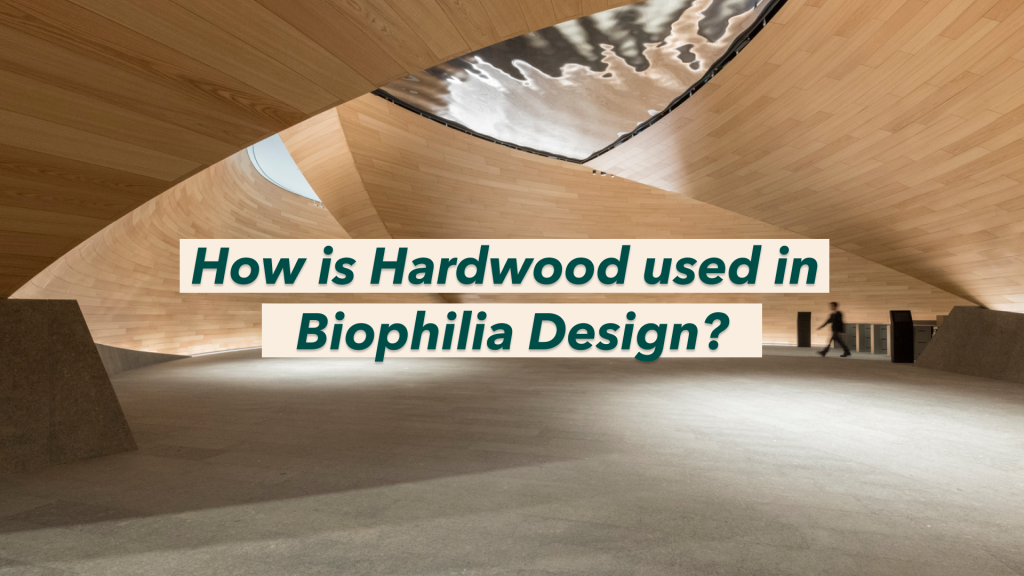

How Hardwood used in Biophilia Design

Every day more and more people are looking to reconnect with nature through hobbies, incorporating nature into their lives and homes and even moving towards more rural areas. The act of reconnecting with nature is called biophilia. The easiest way to connect with nature as a human is by bringing the outdoors indoors. This is a concept called Biophilic Design.

Today, many interior designers are using more natural colors and elements like hardwood, bamboo, and stone in spaces to bring clients’ biophilic design dreams to life. In recent years, more corporate buildings, hotels, and homes have been designed using biophilia, incorporating plants and trees, natural light, hardwood, and more. A recent example is Bloomberg’s European HQ, designed by Foster + Partners. Foster + Partners is a global studio for architecture, engineering, urban and landscape design, rooted in sustainability. They have added a unique and inviting natural touch on Bloomberg’s new London headquarters, with an overall theme of sustainability. It is a great example of sustainable development and biophilia design coming to life:

Designers and architects look at their creations using a biophilic design angle to have a long-term, sustainable impact on people and the world around us. Incorporating hardwood in their biophilic design creates spaces people will resonate with and feel warm in. Hardwood is an extremely durable and versatile material. It gives a natural feel to a space while establishing a connection to the outdoors. You can use variations of hardwood like basswood, black cherry, black walnut, hard maple, hickory, red oak, white oak and white ash to bring any biophilic design concept to life. A few examples of the versatility of hardwood can be found in:

- Flooring: Using hardwood give calm aesthetic, while having a positive impact on the enviroment and has long term durability than using alternatives.

- Walls: If you think of a library what comes to mind? Typically, peace and quietness. Wooden walls in libraries create a sense of calmness to help promote learning and focus.

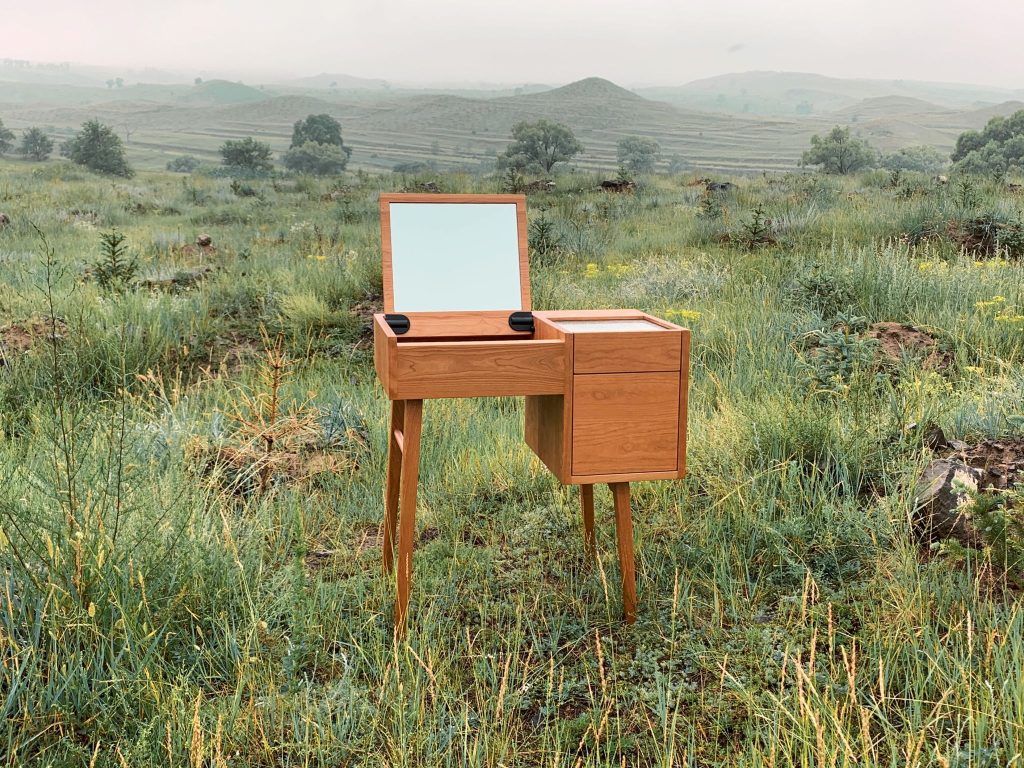

- Furniture: For generations, hardwood has always been used in furniture manufacturing and gives a timeless look when incorporated into residential and commercial buildings.

The three core principles of biophilic design, Nature in the Space, Natural Analogues, and Nature of the Space, are used by architects and designers in flooring, building, and furniture to reflect a feeling of nature.

Nature of Space is the most common and easiest way to bring biophilia into any design. Examples would include indoor plants, waterfalls, and fish tanks.

Natural Analogues, or man-made elements that mimic nature, come to life using materials such as hardwood, ceramics, wood, stone, patterns and organic forms.

Nature of Space is mostly used by architects to make a personal feeling a certain way in a space, using open views and floor plans. Working interchangeably, these three principles are pivotal in biophilia designs.

Biophilia Architecture using Hardwood

Hardwood products can bring a warm, relaxing, stress-free feeling to any space, creating an optimal living and working environment. It has been proven that incorporating elements of hardwood throughout a building or home can lower blood pressure, reduce stress and help one feel more relaxed. In 2019, the NIH conducted a study on hardwood and the impact it has on one’s health and concluded that, “usage of wooden materials verifies their regenerative and positive impact on the human nervous system, through the appealing aesthetics (color, texture, and structures), high contact comfort, pleasant smell, possibility to regulate air humidity, volatile organic compound emissions (VOC-emissions), and acoustic well-being in the space.”

Architects use hardwood to cultivate a sensual experience through senses like your vision, touch and smell to bring the biophilic feeling into their designs. Foster + Partners designed Bloomberg’s European Headquarters and heavily relied on the three core principles of biophilia to do so. The new building has rolling walls of glazed hardwood incorporated inside and outside the headquarters. Also, natural ventilation occurs because of the way the fins on the building were angled, allowing for maximum sunlight exposure throughout:

What are the 5 senses of Biophilic Design?

Biophilic design plays on our senses to add elements of nature into a space, making our minds think we are surrounded by nature indoors. Here are the 5 senses of biophilic design:

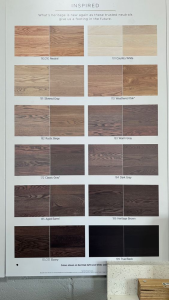

- Visual: Using different species of hardwood brings a unique and warm experience to a space. When choosing a specific hardwood, you can use different species and colors to create the combination that feels right to the space. A common hardwood species combination is Walnut and Maple as it creates a contrast between light and dark wood tones.

- Touch: The texture of hardwood can resonate with people and connect them to the outdoors, all while being inside. You can incorporate different grains to enhance the feeling of the wood in your space. Fake wooden products do not provide the same sensory experience as hardwoods do.

- Scent: Hardwood gives off a natural, organic scent. This creates calming effects and makes for a positive, relaxing experience. The U.S. Environmental Protection Agency (EPA) found that integrating hardwood floors improve indoor air quality because they don’t harbor microorganisms, allergens, or pesticides that can be tracked in from outdoors.

- Hearing: Incorprating water, birdsong, and rustling leaves through water features, soundscapes, or open windows can foster a tranquil environment. Specifically using a material like hardwood, that controls sound frequencies and reduces overall echos in rooms.

- Taste: If you think of a garden, you have an area where you have the opportunity to plant and grow your food, while harvesting living plants before your eyes.

Biophilia and Interior Design

When it comes to interior design, biophilia has the magic to promote overall well-being. By transforming spaces using natural light, organic textures, and materials like hardwood, you can create an entire ecosystem in any building and create a sense of peace and tranquility.

To create a special place using nature in your home, you can integrate hardwoods in flooring, walls and countertops. This can add an organic and earthy touch that connects to the outside world. Oliver Health is a well known interior design consultancy, specializing in projects that promote wellbeing and biophilia design. They have partnered with companies like Westfield, to promote biophilia design concepts in vacant store fronts to show how you can incorporate biophilia design in your own home.

Envision walking through your home with beautiful hardwood complimented by wooden walls and countertops that create a flow between indoors and outdoors. Gutchess Lumber plays a pivotal role in biophilic vision by providing high-quality hardwood. Integrating biophilia and using natural elements like hardwood can cultivate a sanctuary for people to connect with nature. Hardwood has a timeless appeal when used in interior designs. By using Gutchess Lumber, you can leverage hardwood to invite the outdoors into any building, making it a true retreat.

Gutchess Lumber has been manufacturing hardwood for over 100 years and has perfected their process to produce the highest-quality hardwood. Their lumber is used to make furniture, buildings, cabinets and so many other wooden products. Using the highest-quality hardwood you are able to enhance your space to make it beautiful, promoting a healthier, cleaner and more natural living environment bringing a goal of biophilia design to life.