Incorporating Hardwood and Biophilic Design in Architecture and Interior Design

As we become more aware of the built environment’s impact on our health and well-being, designers and architects are increasingly turning to biophilic design to create spaces that promote human health and happiness. Biophilic design is an approach to architecture and interior design that emphasizes the connection between people and nature. By incorporating natural elements, such as hardwood, plants, water, and natural light, into building design, biophilic design creates restorative, soothing spaces that promote overall health.

Benefits of biophilic design in architecture and interiors

Incorporating biophilic design into architecture and interior design can have several benefits. For example, studies have shown that exposure to natural light can improve mood, reduce stress, and increase productivity. Incorporating plants and greenery into a space can also improve air quality, reduce noise levels, and help to create a sense of calm and tranquility. Furthermore, using natural materials, such as hardwood and stone, can create a sense of warmth and comfort often lacking in modern, industrial-style buildings.

Key principals of biophilic design

One of the key principles of biophilic design is creating a connection between indoor and outdoor spaces. This can be achieved by using large windows, balconies, and green roofs that allow people to see and interact with nature from within the building. By blurring the boundaries between indoor and outdoor spaces, biophilic design creates a sense of continuity that is both calming and restorative.

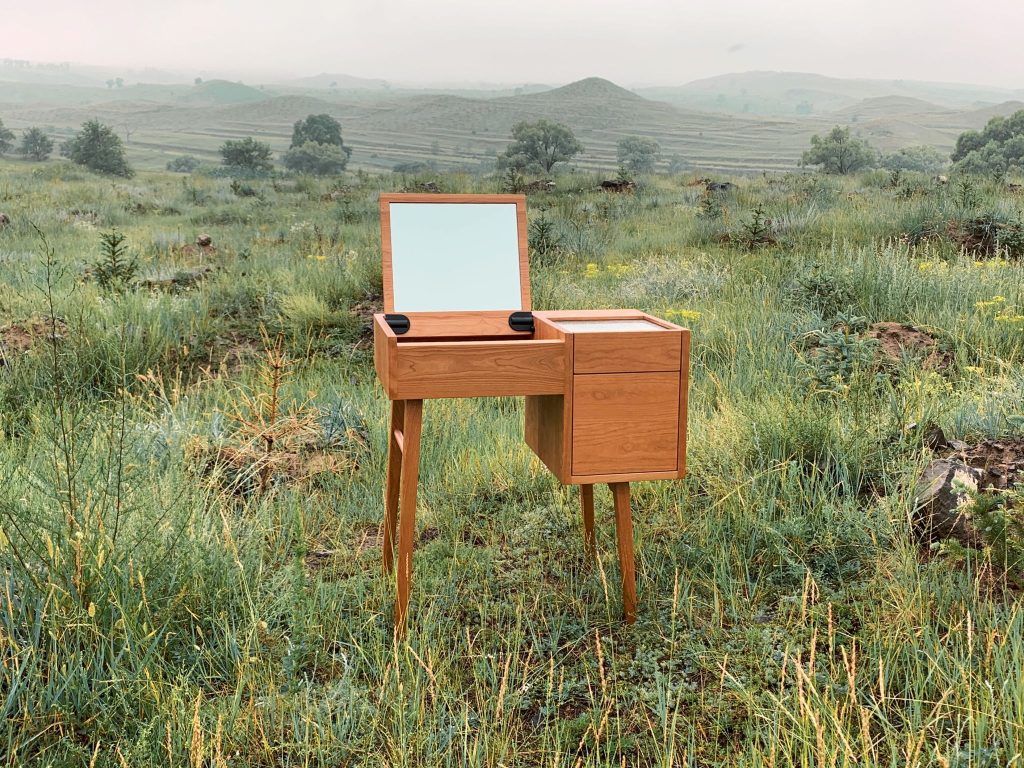

Another important aspect of biophilic design is using color and texture to create a natural and organic feel. For example, using natural hardwood or stone walls can create a sense of calm and depth often lacking in modern, minimalist designs. Similarly, using soft, natural fabrics and materials, such as wool and cotton, can create a sense of comfort and relaxation often lacking in synthetic materials.

How interior designers and architects use hardwood in biophilic design

Interior designers and architects often incorporate hardwood into biophilic design because it is a sustainable and eco-friendly material that connects people to nature. Hardwood provides a sense of warmth and natural beauty that can help to create a sense of calm and tranquility. It also has many practical benefits, such as durability, versatility, and resistance to wear and tear. By using hardwood in building design, designers can also promote carbon sequestration and storage, which helps to reduce the amount of carbon dioxide in the atmosphere and mitigate the effects of climate change. Whether used in flooring, furniture, or wall paneling, hardwood is a versatile and aesthetically pleasing material that can help bring nature’s beauty and serenity into interior spaces.

In conclusion, incorporating biophilic design into architecture and interior design can have many benefits, including improved health and well-being, increased productivity, and a greater sense of calm and tranquility. By incorporating natural elements, such as plants, water, and natural light, into building design, biophilic design creates restorative and aesthetically pleasing spaces. As we prioritize human health and well-being in building design, biophilic design will likely become an increasingly important trend in architecture and interior design.